Abs: Because detecting UST systems releases quickly helps stop contamination before it spreads from UST sites, EPA requires owners and operators detect releases from their UST systems. EPA allows three categories of release detection: interstitial, internal, and external. These three categories include seven release detection methods.

Introduction

Because detecting UST systems releases quickly helps stop contamination before it spreads from UST sites, EPA requires owners and operators detect releases from their UST systems. EPA allows three categories of release detection: interstitial, internal, and external. These three categories include seven release detection methods.

- Interstitial method – secondary containment with interstitial monitoring; secondary containment and under-dispenser containment

- Internal methods – automatic tank gauging (ATG) systems; statistical inventory reconciliation (SIR); continuous in-tank leak detection

- External method – monitoring for vapors in the soil; monitoring for liquids on the groundwater

- Other methods approved by the implementing agency

Secondary Containment with Interstitial Monitoring

EPA allows owners and operators to use this interstitial method – secondary containment with interstitial monitoring – for detecting releases from their UST systems.

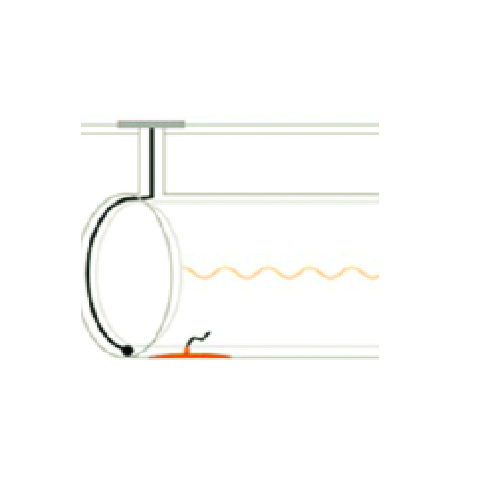

This method detects leaks in the space between the UST and a second barrier. The federal UST regulations describe general performance requirements for interstitial monitoring with double walled USTs, USTs fitted with internal liners, and USTs using interception barriers.

Secondary Containment

- Secondary containment provides a barrier between the tank and the environment. The barrier holds the leak between the tank and the barrier so that the leak is detected. The barrier is shaped so that a leak will be directed towards the interstitial monitor.

- Barriers include:

- Double walled or jacketed tanks, in which an outer wall partially or completely surrounds the primary tank;

- Internally fitted liners (bladders); and

- Leakproof excavation liners that partially or completely surround the tank.

- Clay and other earthen materials cannot be used as barriers.

Interstitial Monitors

- Monitors are used to check the area between the tank and the barrier for leaks and alert the operator if a leak is suspected.

- Some monitors indicate the physical presence of the leaked product, either liquid or gaseous. Other monitors check for a change in condition that indicates a hole in the tank, such as a loss of vacuum or a change in the level of a monitoring liquid between the walls of a double walled tank.

- Monitors can be as simple as a dipstick used at the lowest point of the containment to see if liquid product has leaked and pooled there. Monitors can also be sophisticated automated systems that continuously check for leaks.

Internal Methods

EPA allows owners and operators to use these internal methods – automatic tank gauging, manual tank gauging, statistical inventory reconciliation, and tank tightness testing with inventory control – for detecting releases from their UST systems.

- Automatic Tank Gauging

How does the leak detection method work?

This method uses automated processes to monitor product level and inventory control. A probe permanently installed in the tank is connected to a monitor to provide information on product level and temperature. These systems calculate changes in product volume that can indicate a leaking tank. Automatic tank gauging systems (ATG systems) operate in one of two modes: inventory mode and leak detection mode. In the leak detection mode, ATG systems can be set manually or automatically to perform a leak test. Manual leak tests are in-tank static tests and automatic leak tests are continuous in-tank leak detection tests. When we refer to ATG systems we are referring to testing performed in the in-tank static test mode. ATG systems operating in continuous in-tank leak detection test mode are covered under Continuous In-Tank Leak Detection.

Features of ATG systems include:

- The product level and temperature in a tank are measured and recorded by a computer, this saves labor and time.

- In the inventory mode, the ATG system replaces the use of the gauge stick to measure product level and perform inventory control. This mode records the activities of an in-service tank, including deliveries.

- In the leak detection mode (in-tank static test), the tank is taken out of service and the product level and temperature are measured for at least one hour.

- Note: Some systems, known as continuous ATG systems, do not require the tank to be taken out of service to perform a test. This is because these systems can gather and analyze data during many short periods when no product is being added to or taken from the tank. These systems are discussed under Continuous In-Tank Leak Detection.

2. Statistical Inventory Reconciliation (SIR)

How does the leak detection method work?

For statistical inventory reconciliation (SIR), a trained professional uses sophisticated computer software to conduct a statistical analysis of inventory, delivery, and dispensing data, which you must both collect and supply to the vendor on a regular basis.

SIR methods are distinguished from continuous in-tank leak detection methods by how inventory, delivery, and dispensing data are processed and provide a determination of the release status of the tank (or piping). SIR data are processed on a periodic basis involving a separate analysis that is performed either by a SIR vendor or SIR software. Continuous statistically based in-tank release detection methods process data on an on-going basis occurring in an uninterrupted or nearly uninterrupted manner.

The features of SIR are:

- SIR analyzes inventory, delivery, and dispensing data collected over a period of time to determine whether or not a tank system is leaking.

- Each operating day, the product level is measured using a gauge stick or other tank level monitor. You also keep complete records of all withdrawals from the UST and all deliveries to the UST. After data have been collected for the period of time required by the SIR vendor, you provide the data to the SIR vendor.

- The SIR vendor uses sophisticated computer software to conduct a statistical analysis of the data to determine whether or not your UST may be leaking. The SIR vendor provides you with a test report of the analysis.

3. Continuous In-Tank Leak Detection

How does the release detection method work?

Continuous in-tank leak detection (CITLD) encompasses all statistically based methods where the system incrementally gathers measurements on an uninterrupted or nearly uninterrupted basis to determine a tank’s leak status.

There are two major groups that fit into this category: continuous statistical release detection (also referred to as continuous automatic tank gauging methods) and continual reconciliation. Both groups typically use sensors permanently installed in the tank to obtain inventory measurements. They are combined with a microprocessor in the ATG system or other control console that processes the data. Continual reconciliation methods are further distinguished by their connection to dispensing meters that allow for automatic recording and use of dispensing data in analyzing tanks’ leak status.

4. Tank Tightness Testing

How does tank tightness testing work?

Tightness tests include a wide variety of methods. Other terms used for these methods include precision, volumetric, and nonvolumetric testing.

The features of tank tightness testing are:

- Many tightness test methods are volumetric methods in which the change in product level in a tank over several hours is measured very precisely (in milliliters or thousandths of an inch).

- Other methods use acoustics or tracer chemicals to determine the presence of a hole in the tank. With such methods, all of the factors in the following bullets may not apply.

- For most methods, changes in product temperature also must be measured very precisely (thousandths of a degree) at the same time as level measurements, because temperature changes cause volume changes that interfere with finding a leak.

- For most methods, a net decrease in product volume (subtracting out volume changes caused by temperature) over the time of the test indicates a leak.

- The testing equipment is temporarily installed in the tank, usually through the fill pipe.

- The tank must be taken out of service for the test, generally for several hours, depending on the method.

- Many test methods require that the product in the tank be a certain level before testing, which often requires adding product from another tank on-site or purchasing additional product.

- Some tightness test methods require all of the measurements and calculations to be made by hand by the tester. Other tightness test methods are highly automated. After the tester sets up the equipment, a computer controls the measurements and analysis.

- A few methods measure properties of the product that are independent of temperature, such as the mass of the product, and so do not need to measure product temperature.

- Some automatic tank gauging systems are capable of meeting the regulatory requirements for tank tightness testing and can be considered as an equivalent method. Check with your implementing agency.

5. Inventory Control

How does inventory control work?

Inventory control requires daily measurements of tank contents and mathematical calculations that let you compare your stick inventory (what you’ve measured) to your book inventory (what your recordkeeping indicates you should have). If the difference between your stick and book inventory is too large, your tank may be leaking.

EPA’s booklet, Doing Inventory Control Right, explains how to do inventory control with simple step-by-step directions. The booklet also includes standard forms used to record inventory data.

The features of inventory control are:

- UST inventories are determined daily by using a gauge stick and the data is recorded on a form. The level on the gauge stick is converted to a volume of product in the tank using a calibration chart, which is often furnished by the UST manufacturer.

- The amounts of product delivered to and withdrawn from the UST each day are also recorded. At least once every 30 days, the gauge stick data and the sales and delivery data are reconciled and the month’s overage or shortage is determined. If the overage or shortage is greater than or equal to 1.0 percent of the tank’s flow-through volume plus 130 gallons of product, the UST may be leaking.

External Methods

EPA allows owners and operators to use these external methods – groundwater monitoring and vapor monitoring – for detecting releases from their UST systems.

- Monitoring for Liquids on the Groundwater

This method monitors the groundwater table near an UST for the presence of released free product on the water table. Monitoring wells near the UST are checked frequently to see if petroleum can be detected. The federal UST regulation describes several requirements for use of this method. For example, this method cannot be used if the water table is more than 20 feet below the surface of the ground.

Features of groundwater monitoring are:

- Groundwater monitoring involves the use of permanent monitoring wells placed close to the UST. The wells are checked at least monthly for the presence of product that has leaked from the UST and is floating on the groundwater surface.

- The two main components of a groundwater monitoring system are the monitoring well (typically a well of 2-4 inches in diameter) and the monitoring device.

- Detection devices may be permanently installed in the well for automatic, continuous measurements for leaked product.

- Detection devices are also available in manual form. Manual devices range from a bailer (used to collect a liquid sample for visual inspection) to a device that can be inserted into the well to electronically indicate the presence of leaked product. Manual devices must be operated at least once a month.

- Before installation, a site assessment is necessary to determine the soil type, groundwater depth and flow direction, and the general geology of the site. This assessment can only be done by a trained professional.

- The number of wells and their placement is very important. Only an experienced contractor can properly design and construct an effective monitoring well system. A minimum of two wells is recommended for a single tank excavation. Three or more wells are recommended for an excavation with two or more tanks. Some state and local agencies have developed regulations for monitoring well placement.

What are the regulatory requirements?

- Groundwater monitoring can only be used if the stored substance does not easily mix with water and floats on top of water.

- If groundwater monitoring is to be the sole method of leak detection, the groundwater must not be more than 20 feet below the surface, and the soil between the well and the UST must be sand, gravel or other coarse materials.

- Monitoring wells must be properly designed and sealed to keep then from becoming contaminated from outside sources. The wells must also be clearly marked and secured.

- Wells should be placed in the UST backfill so that they can detect a leak as quickly as possible.

- Product detection devices must be able to detect one-eighth inch or less of leaked product on top of the groundwater.

2. Monitoring for Vapors in the Soil

This method samples for either: product vapors in the soil gas surrounding the UST (sometimes called passive monitoring) or presence of a tracer compound introduced into the UST system (sometimes called active monitoring). Leaked petroleum produces vapors that can be detected in the soil gas. The federal UST regulation describes several requirements for using this leak detection method. For example, this method requires using porous soils in the backfill and locating the monitoring devices in these porous soils near the UST system.

Features of vapor monitoring systems are:

- Passive vapor monitoring senses or measures fumes from leaked product in the soil around the tank to determine if the tank is leaking.

- Active vapor monitoring senses or measures a tracer compound leaked in the soil around the tank to determine if the tank is leaking.

- Fully automated vapor monitoring systems have permanently installed equipment to continuously or periodically gather and analyze vapor samples and respond to a release with a visual or audible alarm.

- Manually operated vapor monitoring systems range from equipment that immediately analyzes a gathered vapor sample to devices that gather a sample that must be sent to a laboratory for analysis. Monitoring results from manual systems are generally less accurate than those from automated systems. Manual systems must be used at least once a month to monitor a site.

- All vapor monitoring devices should be periodically calibrated according to the manufacturer’s instructions to ensure that they are properly responding.

- Before installation, a site assessment is necessary to determine the soil type, ground water depth and flow direction, and the general geology of the site. This can only be done by a trained professional.

- The number of wells and their placement is very important. Only an experienced contractor can properly design and construct an effective monitoring well system. Vapor monitoring requires the installation of monitoring wells within the tank backfill. A minimum of two wells is recommended for a single tank excavation. Three or more wells are recommended for an excavation with two or more tanks. Some state and local agencies have developed regulations for monitoring well placement.